The core of intelligent robots, autonomous driving, and automation: sensors and manufacturing implementation

Time:2024-03-28

Views:1

Whether it‘s intelligent machinery or automated assembly lines, whether it‘s precision robots or intelligent electrical circuits, two core factors play a decisive role: power supply and mechanical control!

Leaving the power source (energy), everything becomes a decoration! Without mechanical control and advanced software, it is impossible to achieve actual functionality.

Energy is a national macro plan, and whether it is the vigorous promotion of clean energy or the West East Power Transmission Project, it all indicates a problem: the future industry needs power support! And the demand will gradually increase, and environmentally friendly clean energy will continue to be embraced by the market.

Mechanical control requires precision components, sensors, industrial software, system assembly, and closed-loop monitoring.

Based on over a decade of experience serving the semiconductor and electronics industries at DRMFG, sensors are at the core of mechanical control.

According to the principles of bionics, sensors are often classified into the following categories:

Photosensitive Sensor - Vision

Sound sensitive sensors - auditory

Gas Sensor - Olfactory Sense

Chemical Sensor - Taste Sensor

Pressure sensitive, temperature sensitive, fluid sensors - tactile

Classification of sensitive components: physical, based on physical effects such as force, heat, light, electricity, magnetism, and sound. Chemistry, based on the principles of chemical reactions. Biological, based on molecular recognition functions such as enzymes, antibodies, and hormones. Usually, according to their basic perceptual functions, they can be divided into ten categories: thermal sensitive elements, photosensitive elements, gas sensitive elements, force sensitive elements, magnetic sensitive elements, humidity sensitive elements, sound sensitive elements, radiation sensitive elements, color sensitive elements, and taste sensitive elements.

Sensors will be classified more and more in the future, because the market division of labor is becoming increasingly detailed, and the development of new industries requires more new sensors!

DRMFG does not produce sensors, but has indeed served more than 20 industries by producing many precision parts and accessories for sensors, helping customers achieve automated and sensitive control!

The rise of new energy vehicles, as well as future autonomous driving, RADAR sensors and Acoustic sensors, are often compared and researched by engineers.

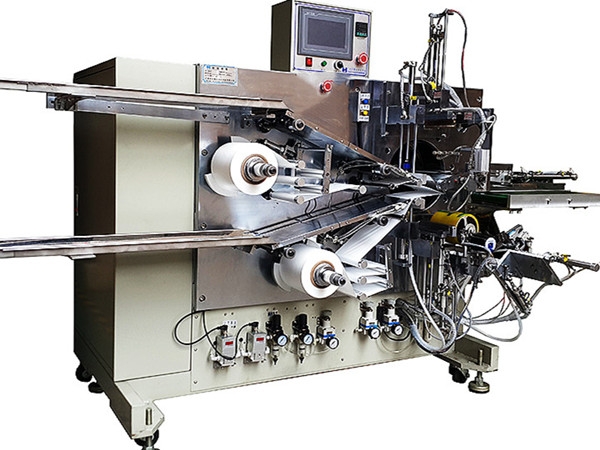

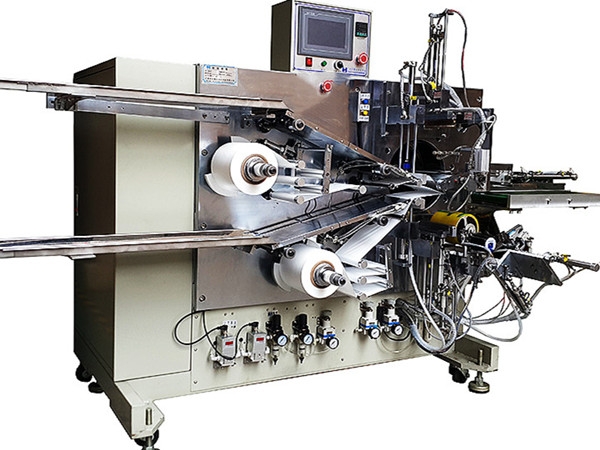

In the LED and semiconductor industries, the use of high-speed robotic arms requires the coordination of precision fingers and suction cups.

Biopharmaceuticals and pharmaceutical packaging require high-speed conveyor belts, online weighing and detection, as well as defect classification systems.

The medical equipment industry requires countless stainless steel parts that are precise, reliable, rust proof, and durable.

DRMFG works hand in hand with customers to develop, manufacture, and implement new products, accompanying each other, complementing each other‘s strengths, and forward together.